Mechanical Testing of Materials

Mechanical Testing of Materials

Mechanical testing of materials is essential to ensure that components meet required standards and design specifications. Using advanced techniques and precision instruments, we analyze the ability of materials to withstand different stresses, providing key insights to improve production processes.

Our service, primarily aimed at companies in the metalworking sector, includes compression, tensile, bending, impact, hardness, and other technological tests that assess the mechanical properties of materials. We operate both in our laboratory and directly at customer sites, delivering reliable and detailed results to support product design and certification.

When to Perform a Mechanical Test

A mechanical test is essential to evaluate material performance under physical stress. It is particularly useful during quality control and is carried out during the development of new products, to validate the declared properties of materials or verify compliance with industry standards or customer specifications.

Our Full Range of Mechanical Tests

Thanks to advanced technologies and specialized expertise, we perform a wide variety of mechanical tests on materials. From tensile strength determination to hardness measurement, we help companies certify quality and optimize their production processes.

- Metallographic Analysis

We study the internal characteristics of materials, such as phases, grain size, and non-metallic inclusions, to evaluate quality and compliance with standards. These analyses provide essential information to optimize production processes and ensure high performance.

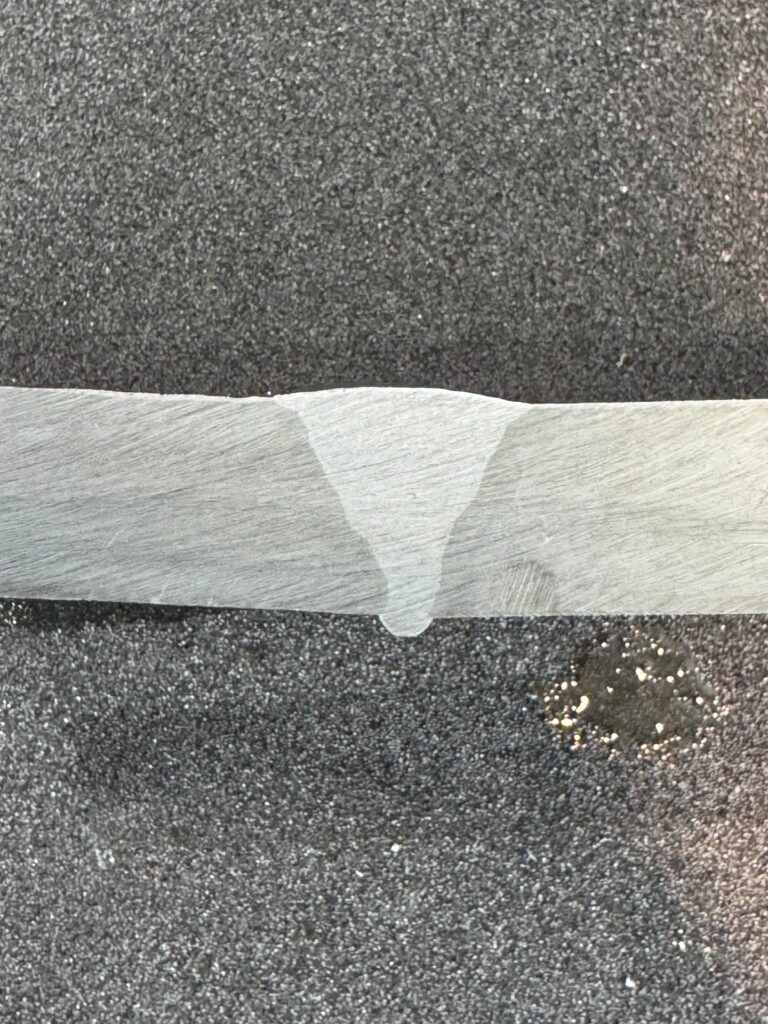

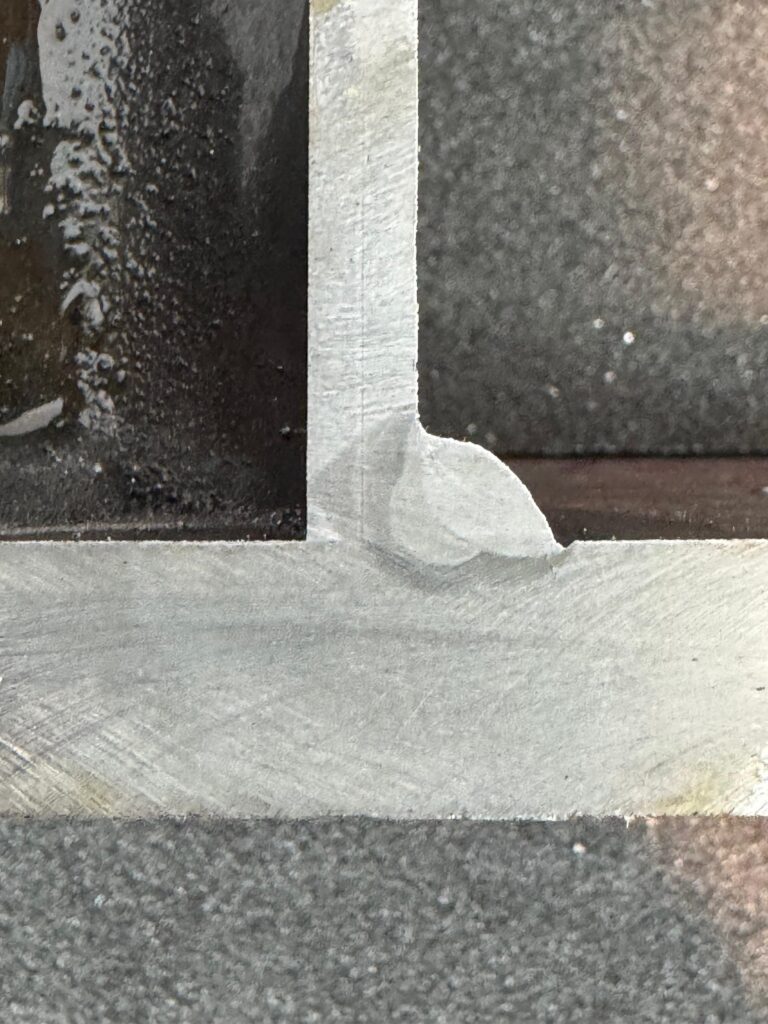

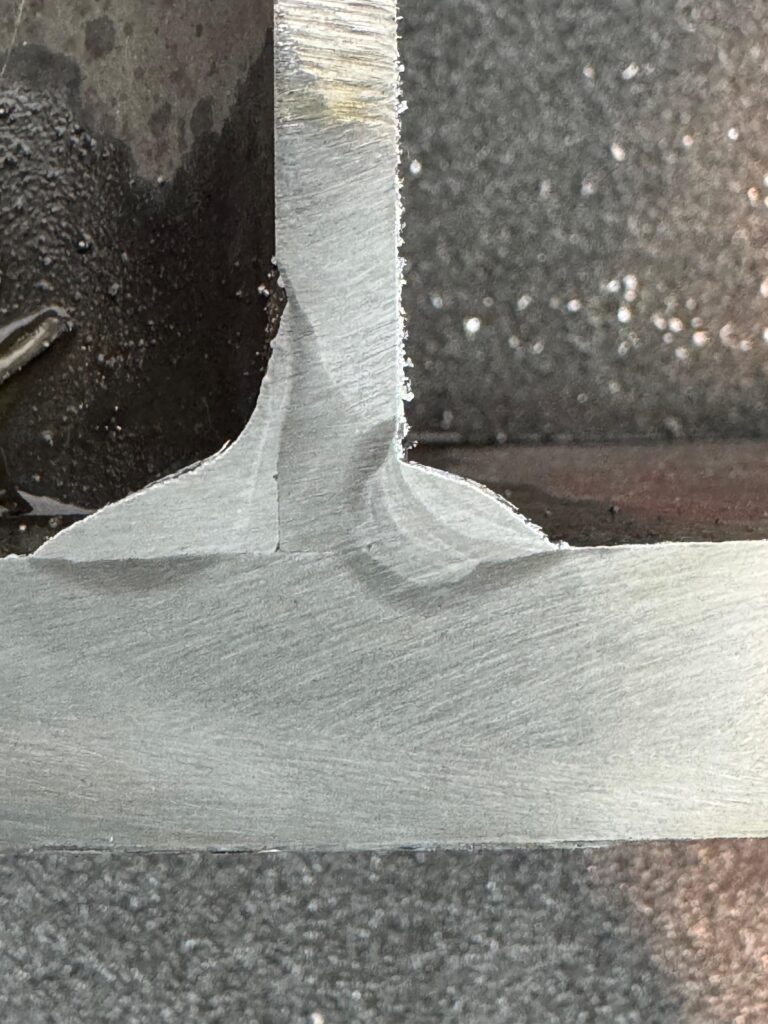

- Macroscopy for Surface Defects

We carry out macroscopic examinations to detect defects such as cracks, inclusions, or porosity on material surfaces. These analyses help prevent structural issues and ensure the suitability of parts for critical applications.

- Micrography for Crystal Structure

We analyze the crystal structure of steel to verify that internal properties meet the required specifications. This check is crucial to ensure that materials perform correctly under expected stresses.

- Chemical Analysis of Materials

Using CCD spectrometers, we analyze the chemical composition of metal alloys. These tests ensure material quality, highlighting any anomalies or contamination.

- HB Hardness on Large Components

We test the Brinell hardness of large components using the ERNST or POLDI calibrated pin system. This method allows for testing complex parts without compromising their integrity.

- Hardness Testing with Bench Durometer

We perform HRC, HRA, HB, and HV10 hardness tests on samples, determining mechanical properties with high precision. These tests are essential for assessing material resistance under various stresses.

- Microhardness for Heat Treatments

We measure the depth of heat treatments to verify that processes have correctly altered mechanical properties — crucial for ensuring optimal performance.

- Microhardness for Coatings

We calculate coating thickness to ensure it meets quality standards. These tests assess the effectiveness of surface protections against wear and corrosion.

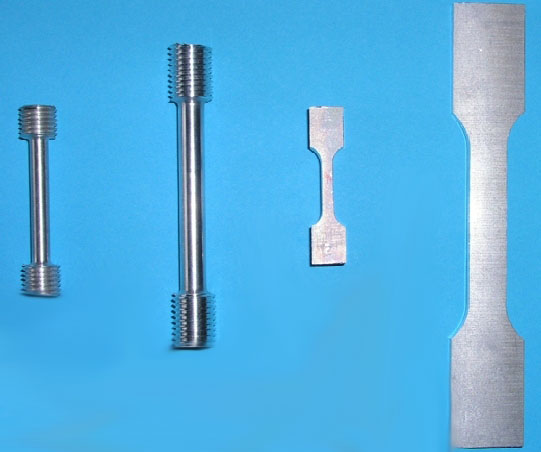

- Technological Tests on Materials

We perform compression, tensile, bending, shear, and impact tests to evaluate key mechanical properties. These data are essential for the use of materials in complex industrial applications.

- Corrosion Resistance Tests

Through salt spray testing, we simulate extreme conditions to verify material resistance to corrosive agents — essential for the chemical and marine industries.

- Failure Analysis

We analyze mechanical component failures to identify the cause of breakage. These studies help improve design and prevent future errors.

- Batch Characterization

We verify production batches to ensure homogeneity and quality of supplied materials. These checks certify compliance with required standards.

Certified Testing

The Material Testing Process

With years of experience in metrology, we have developed a dedicated department for mechanical testing of metallic materials. Our technological tests follow an organized process to ensure that the mechanical and chemical properties of materials meet required standards.

1. Sample Preparation

Materials are selected and prepared according to technical specifications for each test type. This phase is essential for obtaining accurate and representative results.

2. Test Execution

Using advanced instruments, samples undergo tests such as tensile, compression, hardness, or corrosion resistance — depending on needs. Each test follows strict protocols.

3. Data Analysis

The data collected during testing are analyzed to determine the mechanical, chemical, or technological characteristics of the material, ensuring compliance with required standards.

4. Report Preparation

A detailed report is produced, documenting results and certifying material properties. This document ensures traceability and quality assurance.

FAQs on Mechanical Testing

Mechanical and technological testing of materials is essential to guarantee the quality and safety of metals and alloys used in various industrial sectors. Below are answers to the most common questions to help you better understand these processes and their benefits.

What are mechanical tests on materials?

Mechanical tests determine key characteristics such as strength, hardness, elasticity, and ductility. Through specific tests, material performance is evaluated under various conditions to ensure compliance with design and technical standards.

What is the purpose of mechanical testing on metals?

These tests analyze the behavior of metallic materials under stress, such as tension or compression. They are fundamental to identifying structural limits and ensuring that selected metals guarantee safety and durability in final products.

What are the main types of mechanical tests on metallic materials?

The main technological tests include tensile, compression, hardness (Brinell, Vickers, Rockwell), impact, and corrosion resistance tests. Each test focuses on a specific aspect — from static or dynamic load resistance to surface hardness or environmental durability.

What is the difference between mechanical and technological tests?

Mechanical tests focus on determining physical properties such as hardness or strength, while technological tests assess material workability and behavior during manufacturing, providing useful insights for process optimization.

Where are these tests performed?

Mechanical and technological tests on metals are conducted in our certified laboratory, equipped with advanced instruments for precise and repeatable measurements. Specialized technicians perform the tests following standardized procedures, providing reliable results and internationally recognized certifications.

Also Discover Non-Destructive Testing

Non-destructive testing is a key process to verify the integrity and characteristics of materials and structures without affecting their usability.