NDT

NON-DESTRUCTIVE TESTing

NON-DESTRUCTIVE TESTING

Non-Destructive Testing Services

We analyze materials and components without compromising their integrity, ensuring quality, safety, and compliance with required standards.

Non-destructive testing (NDT) is essential for assessing the condition of materials and components without altering their structure.

Among our NDT services, we offer techniques such as ultrasonic testing, radiography, liquid penetrant testing, and magnetic particle testing to detect anomalies and evaluate both internal and surface properties of materials. We operate in laboratories as well as on-site at client facilities, providing precise, documented results to support safety and certification requirements.

These advanced analyses allow defect detection, ensure product reliability, and prevent potential failures, making them a key tool for quality control and preventive maintenance.

Non-Destructive Testing (NDT)

When to Perform

NDT is essential to verify the integrity and quality of a component during production, maintenance, or to ensure compliance with safety regulations.

Visual inspections, liquid penetrant testing, magnetic particle testing, and ultrasonic testing allow precise detection of defects, providing accurate and reliable analysis.

All Our Non-Destructive Testing Services

Non-destructive tests provide accurate analysis of materials and components without compromising their integrity. We offer a complete range of advanced techniques to detect defects, verify compliance, and ensure maximum quality across all sectors.

– Visual Testing (VT)

Visual inspection is the first step in non-destructive testing, particularly for evaluating welds and mechanical components. Using direct observation or optical tools such as magnifying lenses or cameras, macroscopic defects such as cracks, deformations, or surface discontinuities can be quickly identified.

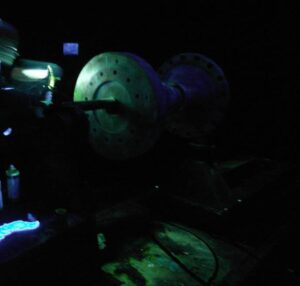

– Liquid Penetrant Testing (PT)

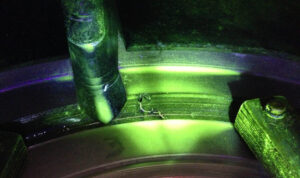

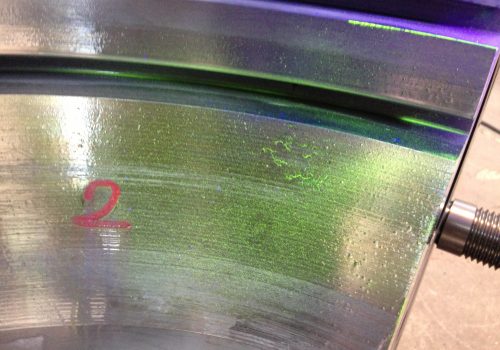

Liquid penetrant testing is suitable for highlighting surface defects on non-porous materials and is particularly effective for inspecting welds, castings, and machined surfaces. A colored or fluorescent liquid is applied to the component surface and allowed to penetrate any discontinuities. After removing excess liquid and applying a developer, defects become visible.

– Magnetic Particle Testing (MT)

Magnetic particle testing is used to detect surface or near-surface cracks in ferromagnetic materials. The component is magnetized, and ferrous particles applied to the surface accumulate at discontinuities, revealing defects. This reliable and versatile technique is often used for welds, castings, or forged parts.

– Ultrasonic Testing (UT)

Ultrasonic testing uses high-frequency sound waves to detect internal defects in materials. The sound wave penetrates the component and reflects in the presence of discontinuities such as inclusions, porosity, or delamination. This method is essential for analyzing solid and thick materials with high precision without compromising component integrity.

Certified Testing

Accredited mechanical testing

Specialized metrology laboratory for NDT

The NDT Process on Materials

Non-destructive testing ensures the integrity and properties of components and structures without compromising their usability. Using advanced methodologies and specific instruments, we detect surface and internal defects, ensuring each element meets required quality standards and is safe for its intended use.

1. Material Preparation

Materials are carefully prepared before NDT to ensure the surface is suitable for analysis. This includes cleaning to remove contaminants or residues that could affect test results.

2. Selection of Testing Method

Depending on material characteristics and testing objectives, the most suitable NDT method is selected, such as visual inspection, ultrasonic testing, or magnetic particle testing.

3. Execution of the Test

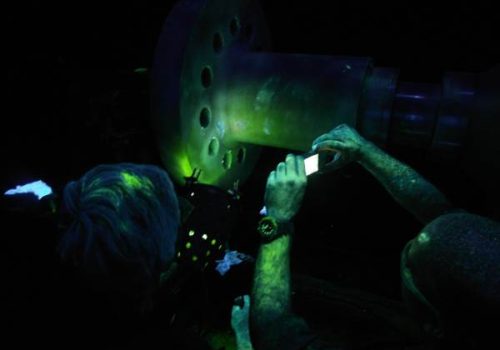

The selected method is applied using specialized equipment and qualified personnel. Detailed data are collected to identify any surface or internal defects.

4. Analysis and Reporting

Test results are analyzed to determine the suitability of the material or component. A comprehensive report is provided, including conclusions and recommendations for corrective actions or improvements.

Frequently Asked Questions About NDT

Non-destructive testing (NDT) ensures the reliability and safety of materials and components without altering their structure. Below, we answer the most common questions about these advanced analysis techniques.

What is Non-Destructive Testing (NDT)?

NDT consists of tests used to verify the quality and integrity of materials and components without compromising their use. Methods such as ultrasonic testing or liquid penetrant inspection detect surface or internal defects, ensuring compliance with safety and quality standards in demanding industrial sectors.

What are the main advantages of NDT?

Unlike destructive testing, NDT inspects materials and components without damaging them, increasing operational and economic efficiency since tested parts can be used directly in production. NDT provides accurate and reliable analysis across a wide range of materials and geometries.

Which sectors benefit from NDT?

NDT is widely used in aerospace, automotive, industrial manufacturing, and construction. It is essential for verifying the integrity of critical structures, welds, pipelines, and mechanical components, ensuring safety, quality, and durability.

Who can perform NDT?

NDT must be performed by qualified personnel certified according to standards such as UNI EN ISO 9712. This ensures accurate, professional testing using advanced instruments to deliver reliable, detailed results.

What is Liquid Penetrant Testing?

Liquid penetrant testing reveals surface defects on non-porous materials by applying a colored or fluorescent liquid to the component surface, allowing it to penetrate any discontinuities. After removing excess liquid and applying a developer, defects—especially in welds, castings, and machined surfaces—become visible.

Become a Measurement Instruments Specialist

Discover our metrology training courses. Become a specialist in measurement instruments and master the use of precision equipment.

Explore Material Testing Services

Mechanical testing of metallic materials ensures their strength, quality, and suitability for end use, meeting required standards and project specifications.