Instrument calibration service

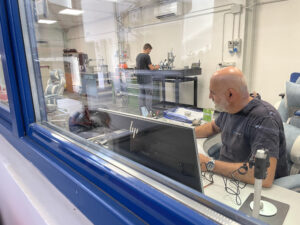

Metrology at the service of your performance. We are a unique interlocutor with a dedicated laboratory and independent experts in the calibration service.

We check and adjust the accuracy of measuring instruments, ensuring their long-term efficiency.

In industries that require strict quality controls and regulatory compliance, our instrument calibration service adds significant value to a company’s credibility. Thanks to our expertise, accumulated experience, and collaboration with leading laboratories across the country, we have become a trusted reference for precision instrument calibration.

Our third-party calibration service involves adjusting laboratory instruments on the client’s premises in accordance with ISO 9001 standards. The service includes thorough testing and precise adjustments carried out at our laboratory—or at one of our partner laboratories—along with the issuance of a final certificate confirming the calibration of the instruments.

What type of calibration are you looking for?

Measurement instrument calibration

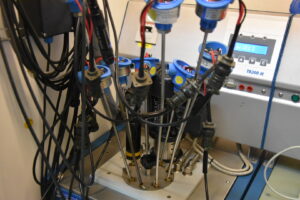

F-Gas instrument calibration

We offer a measurement instrument calibration service aimed at companies in manufacturing, quality control, or laboratories that use a wide range of devices to perform precise and reliable measurements. Instrument calibration involves conducting accurate tests, making adjustments, and verifying performance against required standards. Check the list below to see which equipment can be calibrated at our laboratory.

F-Gas instrument calibration is a specialized service for devices used in monitoring and measuring fluorinated gases. This calibration ensures compliance with European environmental regulations and is essential for professionals in the refrigeration and air conditioning sectors, demonstrating a commitment to sustainability and environmental safety.

Measurement Instrument Calibration – Length Sector

Dial Bore Gauges (without comparator)

Check of the measuring probe travel at 21 points, recording of the maximum error, repeatability, and reversal error.

Laser Aligners

Check of the error in X and Y between receiver and transmitter.

Calipers for External or Depth Measurements up to 2000 mm

Measurement of external dimensions at at least 9 points along the scale, internal and depth rod measurements at two points, verification of internal and external parallelism, repeatability.

Special Calipers for the Railway Sector

Verification according to the manufacturer’s specifications.

Linear Comparators and Transducers (rod and lever type) with a range up to 100 mm

Verification of the measuring range at at least 23 points with both incoming and outgoing rods, recording of Fmax errors and repeatability.

Goniometers

Verification of 9 angles between 0–90°.

Spirit Levels

Verification of 9 angles between 0–90°.

External, Internal, and Depth Micrometers

Verification at multiple points across the measuring range, check (where applicable) of flatness deviation of fixed and movable surfaces, parallelism deviation, correction, zeroing, repeatability.

Thickness Micrometers

Verification of the average thickness of the submitted sample.

Measuring Tapes and Laser Measures

Verification of graduations with 1 m increments.

Thickness Gauges

Verification of the thickness of each blade.

Micrometer Heads

Verification at multiple points across the measuring range.

Depth Gauges

Verification of the measuring range at 12 points.

Measurement Instrument Calibration – Other Sectors

FORCES AND MASSES

Scales

Verification using standard weights on the pan and check for off-center load.

Load Cells

Verification of indication error in compression, tension, or both.

Torque Wrenches

Verification of readings at three points along the scale with 5 repetitions, check of square size and unit format, indication of maximum deviation detected.

Dynamometers

Verification of indication error in compression, tension, or both.

Tensile/Compression Machines

Verification of indication error in compression, tension, or both.

Standard Weights

Verification of nominal value using a reference scale.

PRESSURE

Pressure Gauges 0–700 bar

Verification of the scale at 6 points in increasing and decreasing pressure, indication of deviation, hysteresis error, and repeatability.

Pressure Transducers

Verification of the scale at 6 points in increasing and decreasing pressure, indication of deviation, hysteresis error, and repeatability.

ELECTRICAL QUANTITIES

Power Supplies

Verification of required quantities according to manufacturer or customer specifications.

Ammeters

Verification of required quantities according to manufacturer or customer specifications.

Electrical Calibrators

Verification of required quantities according to manufacturer or customer specifications.

Generators

Verification of required quantities according to manufacturer or customer specifications.

Frequency Generators

Verification of quantities according to manufacturer or customer specifications.

Insulation Testers

Verification of required quantities according to manufacturer or customer specifications.

Multimeters

Verification of required quantities according to manufacturer or customer specifications.

Oscilloscopes

Verification of required quantities according to manufacturer or customer specifications.

Clamp Meters

Verification of required quantities according to manufacturer or customer specifications.

RCL Bridges

Verification of required quantities according to manufacturer or customer specifications.

Resistors

Verification of required quantities according to manufacturer or customer specifications.

Voltmeters

Verification of required quantities according to manufacturer or customer specifications.

Vibrometers

Verification of required quantities according to manufacturer or customer specifications.

TECHNOLOGICAL CHARACTERISTICS

Bench Durometers

Direct or indirect verification.

Portable Durometers

Indirect verification using reference blocks.

SHORE Durometers

Indirect verification with Shore samples at at least 7 points on the scale.

Hardness Reference Samples

Verification of nominal value using a calibrated durometer.

Ultrasonic Thickness Gauges

Probe verification at at least 6 points across the measuring range.

Ultrasonic Flaw Detection Instruments

Verification according to ASTM 317 standard.

TEMPERATURE AND ENVIRONMENTAL CONDITIONS

Thermometers

Verification of one sensor at 5 measurement points between -40 °C and 650 °C.

Hygrometers

Verification at three points of relative humidity.

Thermo-Hygrometers

Verification at three points of humidity and three points of temperature.

Pyrometers

Verification at three points with a maximum range of 1200 °C.

Lux Meters

Verification of the measuring range at 3 points using a light source.

UV-A and UV-B Radiometers

Verification of radiation intensity at the distance required by the customer, at one point.

Combustion Analyzers

Analysis of the gas cells or mixtures present in the instrument.

Anemometers

Verification of air velocity only.

Tachometers and Revolution Counters

Verification of optical, contact, or stroboscopic systems within the range specified by the customer.

Analog or Digital Stopwatches

Verification by comparison with a calibrated reference within the time range required by the customer.

Oven and Furnace Characterization

Verification of chamber uniformity with up to 16 control points.

F-Gas Instrument Calibration

Digital Manifold Gauges

Measure pressure and temperature in refrigeration systems.

Infrared Leak Detectors

Detect refrigerant gas leaks using infrared technology.

Electronic Scales

Check the weight of refrigerant gases during charging/discharging operations.

Digital and Analog Vacuum Gauges

Measure the vacuum level in refrigeration systems.

Digital Thermometers

Accurately measure temperature in various environments and processes.

Analog Manifold Gauges

Monitor pressure and temperature in refrigeration circuits using traditional methods.

Heated Diode Leak Detectors

Detect gas leaks using heated diode sensors.

Temperature, Pressure, and Humidity Probes

Measure environmental and operational parameters with precision.

Analog Vacuum Gauges

Check the vacuum level in refrigeration systems.

Clamp Meters

Measure electric currents without interrupting the circuit.

The calibration process

The instrument calibration process verifies the correspondence of a device’s graduated scale with the quantities to be measured, within certified standards.

Calibration is essential to improve accuracy and minimize measurement errors. This process takes place in multiple stages, from the initial inspection to adjustment, and finally to certification, ensuring reliable measurements that comply with regulations.

1. Initial Inspection

The instrument is checked to verify its physical condition and proper functioning, identifying any anomalies or signs of wear.

2. Comparison with Standards

The instrument’s measurements are compared with certified reference values to assess any deviations.

3. Adjustment and Testing

If necessary, the instrument is adjusted to meet the required accuracy limits and subsequently subjected to further testing.

4. Certificate Issuance

At the end of the process, a calibration certificate is issued documenting the results and ensuring compliance with standards.

5. Identification Label

At the end of the process, an identification label is applied showing the calibration report number, instrument serial number, and the calibration expiry date.

6. Digital Identification Label

Upon request, a QR Code label can be applied to the instrument, linking to the digital version of the calibration report.

All Frequently Asked Questions about the Instrument Calibration Service

Discover everything you need to know about the instrument calibration procedure: from its purpose to how it is performed, and the benefits for your company.

What is instrument calibration?

Measurement instrument calibration is a fundamental operation in which the correspondence between the graduated scale of a measuring instrument and the physical quantity it must measure is checked and, if necessary, corrected. During calibration, the instrument’s readings are compared with a certified standard, ensuring precision and reliability in measurements.

How is instrument calibration carried out?

Calibration of measuring instruments is performed by comparing the readings of the device under test with those of a certified reference instrument, ensuring maximum accuracy. During the process, various values of the quantity to be measured are applied, verifying the accuracy of the instrument being tested. This comparison allows any discrepancies to be identified and, if necessary, the device adjusted to align with the required standards. Our calibration laboratory has approximately 35 reference standards and nearly 100 working standards.

What is the purpose of instrument calibration?

The instrument calibration procedure guarantees accurate and consistent measurement over time. This process, essential for many industrial sectors, enables precise measurements in compliance with regulations, minimizing errors and optimizing company and production processes.

What is the difference between calibration and adjustment of instruments?

Calibration checks and adjusts an instrument’s accuracy by comparing it with certified standards, while technical calibration records any errors without necessarily correcting them. Both calibration and adjustment operations are essential to ensure reliability in measurement activities.